Engine - Tier 4 Final/EU Stage V

Gross Power (SAE J1995:2014)

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Engine - Tier 4 Final/EU Stage V

Net Power (SAE J1349:2011)

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Engine - Tier 4 Final/EU Stage V

Emissions

Meets U.S. EPA Tier 4 Final/EU Stage V emission standards

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Net Power (SAE J1349:2011)

Engine - Tier 4 Final/EU Stage V

Peak Torque - 1,400 rpm

902.00 lb-ft @ 1400 rpm

1223.00 N·m

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Rated Speed

2200.00 r/min

2200.00 r/min

Peak Torque - 1,400 rpm

749.00 lb-ft @ 1400 rpm

1016.00 N·m

Engine - Tier 4 Final/EU Stage V

Rated Speed

2200.00 r/min

2200.00 r/min

Engine Model

Cat® C7.1: configured for two emissions options

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Gross Power (SAE J1995:2014)

Emissions

Brazil MAR-1 and China Nonroad Stage III, equivalent to U.S. EPA Tier 3/EU Stage IIIA

Engine Model

Cat® C7.1: configured for two emissions options

Engine - Tier 4 Final/EU Stage V

Wheels

Axles

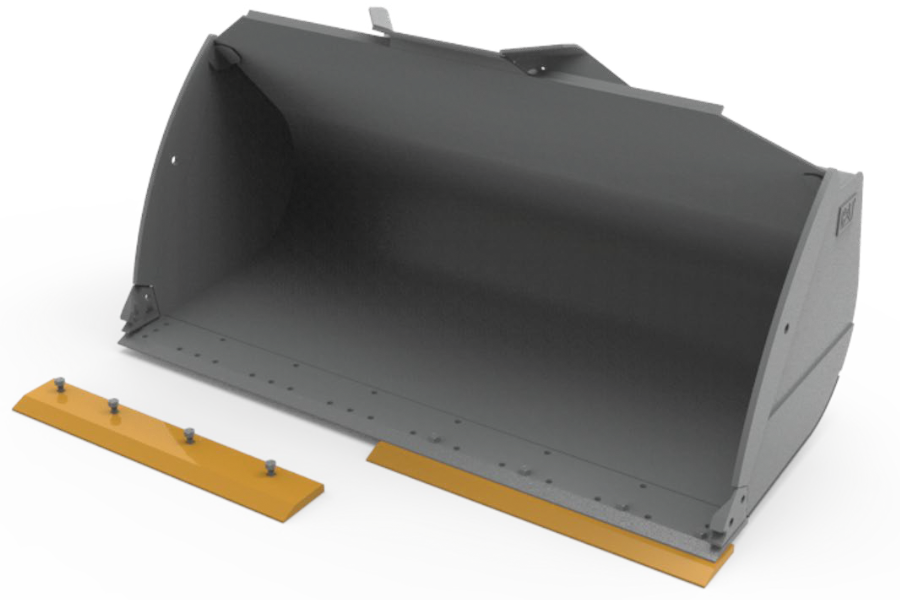

Blades

Maximum Lift Above Ground

Dimensions (Approximate)

Centerline of Rear Axle to Bumper

Service Refill Capacities

Diesel Exhaust Fluid Tank (Tier 4 Final/Stage IV Only)

Differential - Final Drives - Front

Dimensions (Approximate)

Height - Top of Exhaust Pipe

Service Refill Capacities

Cooling System - Tier 3/Stage IIIA Equivalent

Engine

Low Idle Speed

800.00 r/min

800.00 r/min

Service Refill Capacities

Note

Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester) * • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. – Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, API CK-4, and/or ACEA E9 specifications are required. – Diesel Exhaust Fluid (DEF) that meets all requirements defined in ISO 22241-1:2006.

Transmission

Travel Speeds - Forward - Third

Dimensions (Approximate)

Turning Radius - Inside of Push Arms

Hitch to Centerline of Front Axle

Blades

Blade Tilt Angle - Left - Hydraulic

Hydraulic System - Steering

Steering Pressure Limited

Blades

Height - Including Cutting Edge

Dimensions (Approximate)

Transmission

Travel Speeds - Forward - Second

Hydraulic System - Steering

Steering System - Pump

Piston – Variable Displacement

Wheels

Transmission

Travel Speeds - Reverse - Second

Dimensions (Approximate)

Ground Clearance - Bumper

Braking System

Parking Brake

Drum and Shoe, Spring Applied, Hydraulic Released

Hydraulic System

Tilt Cylinder, Double Acting - Bore and Stroke

101.6 mm × 167 mm (4 in × 6.6 in)

Engine

Maximum Altitude - Without Derating

Transmission

Travel Speeds - Forward - First

Dimensions (Approximate)

Hydraulic System

Lift Cylinder, Double Acting - Bore and Stroke

101.6 mm × 627 mm (4 in × 24.7 in)

Axles

Hydraulic System

Pump Flow at 2,111 rpm

23.50 gal/min

89.00 l/min

Blades

Wheels

Service Refill Capacities

Differential - Final Drives - Rear

Dimensions (Approximate)

Blades

Blade Tilt Adjustment - Right

Service Refill Capacities

Blades

Blade Tilt Adjustment - Left

Dimensions (Approximate)

Service Refill Capacities

Blades

Blade Tilt Angle - Right - Hydraulic

Hydraulic System - Steering

Vehicle Articulation Angle

Hydraulic System

Dimensions (Approximate)

Length - With Blade on Ground

Transmission

Transmission Type

Cat Planetary Power Shift

Hydraulic System - Steering

Steering System - Circuit

Hydraulic System

Dimensions (Approximate)

Transmission

Travel Speeds - Reverse - First

Travel Speeds - Reverse - Third

Dimensions (Approximate)

Hydraulic System - Steering

Maximum System Flow

147 L/min @ 2,111 rpm (38.8 gal/min @ 2,111 rpm)

Engine

High Idle Speed

2270.00 r/min

2270.00 r/min

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Machine Sound Level (ISO 6395)

109.00 dB(A)

109.00 dB(A)

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Standard

Note (1)

The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Note (3)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Dimensions (Approximate)

Ground Clearance to Bottom of Bumper

Height to Top of Radiator Guard

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Machine Sound Level (ISO 6396)

Service Refill Capacities

Cooling Systems - Tier 4 Final/EU Stage V

Braking System

Service Brakes

Single Disc Wet (Enclosed) 2 WHL

Dimensions (Approximate)

Ground Clearance to Transmission Guard

Centerline of Rear Axle to Bumper

Overall Machine Length with Straight Blade

Sound Performance - Tier 4 Final/EU Stage V - Standard

Machine Sound Level (ISO 6395)

111.00 dB(A)

111.00 dB(A)

Note (1)

The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Suppression

Note (3)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Sound Performance - Tier 4 Final/EU Stage V - Standard

Note (3)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Suppression

Machine Sound Level (ISO 6395)

110.00 dB(A)

110.00 dB(A)

Operating Specifications - Tier 4 Final/EU Stage V

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Note (1)

The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

Note (2)

The operator sound pressure level uncertainty is ± 2 dB(A)

Dimensions (Approximate)

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Standard

Note (2)

The operator sound pressure level uncertainty is ± 2 dB(A)

Sound Performance - Tier 4 Final/EU Stage V - Standard

Note (2)

The operator sound pressure level uncertainty is ± 2 dB(A)

Dimensions (Approximate)

Ground Clearance to Hitch

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Standard

Note (3)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Suppression

Note (4)

The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Note (4)

The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Suppression

Note (2)

The operator sound pressure level uncertainty is ± 2 dB(A)

Note (1)

The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

Wheels

Service Refill Capacities

Diesel Exhaust Fluid Tank*

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Standard

Machine Sound Level (ISO 6395)

112.00 dB(A)

112.00 dB(A)

Note (4)

The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at the maximum engine cooling fan speed.

Engine - Tier 4 Final/EU Stage V

Net Power (ISO 9249:2007)

Engine Power (ISO 14396:2002)

High Idle Speed

2270.00 r/min

2270.00 r/min

Low Idle Speed

800.00 r/min

800.00 r/min

Maximum Altitude without Derating

Note

Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator.

Engine - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA

Engine Power (ISO 14396:2002)

High Idle Speed

2270.00 r/min

2270.00 r/min

Low Idle Speed

800.00 r/min

800.00 r/min

Maximum Altitude without Derating

Note

Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator.

Hydraulic System - Lift/Tilt

Lift/Tilt System - Circuit

Pilot operated Load Sensing valve with EH

Lift/Tilt System

Variable displacement piston

Maximum Flow at 2,200 rpm

23.50 gal/min

89.00 l/min

Relief Valve Setting - Lift/Tilt

Pilot System

Open center, fixed displacement gear

Pilot Relief Valve Setting

Hydraulic System - Steering

Maximum Flow at 2,200 rpm

38.80 gal/min

147.00 l/min

Relief Valve Setting - Steering

Steering Cycle Times - High Idle

Steering Cycle Times - Low Idle

Dimensions (Approximate)

Height to Top of GPS Antenna

Overall Machine Length with EU Suppression

Sound Performance - Tier 4 Final/EU Stage V - Standard

Operator Sound Level (ISO 6396)

Note (4)

The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at the maximum engine cooling fan speed.

Sound Performance - Tier 4 Final/EU Stage V - Suppression

Operator Sound Level (ISO 6396)

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Standard

Operator Sound Level (ISO 6396)

Sound Performance - Brazil Mar-1 and China Nonroad Stage III, Equivalent to Tier 3/EU Stage IIIA - Suppression

Operator Sound Level (ISO 6396)

Sound Performance - Tier 4 Final/EU Stage V - Suppression EU

Machine Sound Level (ISO 6393)

107.00 dB(A)

107.00 dB(A)

Note (1)

The machine sound power level was measured according to the test procedures and conditions specified in ISO 6393:2008. The measurement was conducted at the rated engine cooling fan speed.

Wheels

Blades

Turning Radius - Outside Corner of Blade

Turning Radius - Inside Face of Pusharm

Engine

Gross Power (SAE J1995:2014)

Net Power (SAE J1349:2011)

Net Power (ISO 9249:2007)

Engine Power (ISO 14396:2002)

Emissions

Option 1 - U.S. EPA Tier 4 Final/EU Stage V

Rated Speed

2200.00 r/min

2200.00 r/min

Emissions

Option 2 - Brazil MAR-1, emitting equivalent to U.S. EPA Tier 3/EU Stage IIIA

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. - If equipped with R134a (Global Warming Potential = 1430), the system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.994 tons).

Engine

Note (1)

Net power available at flywheel when the engine is equipped with fan, air cleaner, aftertreatment, and alternator with engine speed at 2,200 rpm.

Net Power - ISO 9249:2007

Gross Power - SAE J1995:2014

Peak Torque ( 1,400 rpm )

749.00 lbf·ft

1016.00 N·m

Note (2)

Net power available at the flywheel when the engine is equipped with fan, air cleaner, muffler, and alternator with engine speed at 2,200 rpm.

Operating Specifications

Operating Weight (Tier 4 Final/Stage V)

Operating Weight (Tier 3/Stage IIIA equivalent)

Hydraulic System - Lift/Tilt

Cylinders, Double Acting: Lift, Bore, Stroke

101.6 mm x 627 mm (4.0 in x 24.7 in)

Cylinders, Double Acting: Left and Right Tilt, Bore, Stroke

101.6 mm x 167 mm (4.0 in x 6.6 in)

Service Refill Capacities

Diesel Exhaust Fluid Tank

Sound Performance - Tier 4 Final / Stage V

Operator Sound Pressure Level (ISO 6396:2008)

Machine Sound Power Level (ISO 6395:2008)

112.00 dB(A)

112.00 dB(A)

Machine Sound Power Level (ISO 6395:2008)***

109.00 dB(A)

109.00 dB(A)

Operator Sound Pressure Level (ISO 6396:2008)*,***

Machine Sound Power Level (ISO 6395:2008)**

107.00 dB(A)

107.00 dB(A)

Sound Performance - Tier 3 / Stage IIIA

Machine Sound Power Level (ISO 6395:2008)

112.00 dB(A)

112.00 dB(A)

Sound Performance - Tier 4 Final / Stage V

Note (1)

* For machines in European Union countries and in countries that adopt the “EU Directives” and “UK Directives”

Note (2)

** European Union Directive “2000/14/EC” as amended by “2005/88/EC.” and UK Noise Regulation 2001 No. 1701

Note (3)

***Sound suppression equipped

Note (4)

The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 100 percent of the maximum engine cooling fan speed.

Note (5)

The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 100 percent of the maximum engine cooling fan speed.

Note (6)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Sound Performance - Tier 3 / Stage IIIA

Operator Sound Pressure Level (ISO 6396:2008)

Operator Sound Pressure Level (ISO 6396:2008)***

Machine Sound Power Level (ISO 6395:2008)***

110.00 dB(A)

110.00 dB(A)

Note (1)

***Sound suppression equipped

Note (2)

The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 100 percent of the maximum engine cooling fan speed.

Note (3)

The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 100 percent of the maximum engine cooling fan speed.

Note (4)

Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

WARNING

WARNING