Career Paths at Peterson Cat

If you're ready to advance your career, consider Peterson Cat jobs. We are a leading supplier of equipment and service from Caterpillar and other leading manufacturers. Our locations cover California, Oregon, and southwest Washington, offering jobs wherever you call home.

You can find professional opportunities across areas ranging from equipment repair to sales. You'll gain competitive pay and benefits, skills advancement, and more to help you build a career.

Service Technician Careers

Bring your equipment repair and service expertise. We rely on power and earthmoving technicians in the shop and field. Utilize skills like diesel engine repair, generator repair, and electrical power service to keep equipment running smoothly. You can even learn these skills on the job with our training programs.

Our Cat® dealer career paths include the following:

Earthmoving Field Technicians

Travel throughout a broad service area to jobsites or facilities. Use your expertise to service Cat earthmoving equipment. You may also work on models from other top manufacturers. Equipment you will service includes bulldozers, skid steer loaders, excavators, and backhoe loaders.

Power Shop Technicians

Work in a fully equipped service shop, maintaining and repairing diesel engines and power generation equipment. We rely on those with education and practical experience working with diesel engines on and off the highway.

Power Field Technicians

Experience a job where every day is different. As a Peterson Cat power field technician, you will visit facilities and jobsites to repair power generation equipment and marine engines. Your work enables businesses to keep their projects running on schedule.

Other Available Cat® Career Paths

We offer various jobs across technical and nontechnical fields, including:

- Truck drivers: Drive for us. We provide opportunities to deliver heavy equipment to jobsites and businesses across our service area.

- Equipment sales members: Use your communication skills and equipment knowledge to help clients find the models they need for each task.

- Parts experts: As part of our parts department, you can help clients locate the components they need for repairs and service.

- Administrative personnel: As part of our accounting, human resources, marketing, or other teams, you work behind the scenes to keep our company's gears turning.

Why Join Peterson Cat?

When you join us, you work for a company with a long, successful track record in the equipment industry. Our company began in 1936 and remains family-run today. The third and fourth generations of the Peterson family maintain a strong legacy and passionately partner with clients to build a better future.

Our large family of companies includes dozens of locations throughout three states. When you work with us, you will have plenty of career success and advancement. We also enhance our employees' experiences by offering best-in-class benefits. Support yourself and your family with healthcare, retirement plans, life insurance, paid holidays, and more. We also offer training programs like ThinkBIG and Peterson University. Start your technician career or advance your skills with us.

Start Your Career With Peterson Cat

Do exciting and essential work that helps businesses run effectively. Meanwhile, you'll have the chance to grow your career and gain exceptional benefits. Explore technician career paths and other opportunities we offer online. Browse our current open positions.

Rubber Track Special

UP TO 50% OFF CAT RUBBER TRACKS

Until December 31, Peterson Cat is offering big discounts on Genuine Cat rubber tracks, with a special incentive when you buy online.

Cat Advansys Adapters

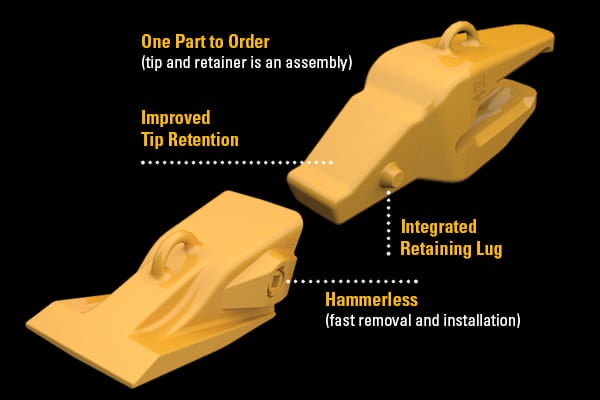

CAT ADVANSYS SYSTEM BENEFITS SUMMARY:

- Improved Productivity: Exclusive tip and adapter features result in the highest productivity Cat system

- Enhanced Reliability: Strongest, most robust adapters Caterpillar® has ever produced

- Hammerless Installation: Quickest hammerless tip removal and installation with a 3/4 inch retainer lock that requires no special tools

- Simplify Installation: Integrated retention components mean no more searching for pins or retainers

- Simplify Retrofitting: Easy upgrading because Advansys adapters drop into the same space as K series

- Simplify Ordering: One part number to order when changing a set of tips

CAT ADVANSYS SYSTEM PERFORMANCE:

- Exclusive performance features such as tapered tip sides offer less drag and higher productivity

- New and optimized tip shapes put wear material where you need it most

CAT ADVANSYS SYSTEM RELIABILITY:

- Stronger adapter noses are designed with up to a 50% stress reduction

- Improved adapter nose geometry reduces sliding wear on adapter nose surfaces extending the life of the adapter

- Improved tip shapes shadow the adapter straps and welds for longer adapter life

- Top covers available for double strap adapters and full adapter covers available for high abrasion flush mount adapters

CAT ADVANSYS HAMMERLESS INSTALLATION AND REMOVAL:

- Half turn of retention locks and unlocks the CapSure retention

- Only a 1/2” or 3/4” breaker bar is required to change the tips

- Retention components come installed in tips

Cat Advansys for Wheel Loaders

Contact Us

Heavy Abrasion

- Use in easy to penetrate high abrasive materials

- Lower penetration ability

- Heavy wear pad for long wear life

Heavy Penetration

- Use in hard to penetrate high abrasive materials

- Very good penetration

- Heavy wear pad for long wear life

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Loader

- Use in low abrasive materials

- Good penetration

- Single top self-sharpening cavity

Coal

- Use in low abrasive materials like coal seams

- Use on loaders to produce a smoother floor

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Cat Advansys for Excavators

Contact Us

Heavy Duty

- Use in moderate abrasive materials

- Good penetration

- Single top self-sharpening cavity

General Purpose Excavator

- Use in low abrasive materials

- Good penetration

- Single top-self-sharpening cavity

Wide

- Use on excavators to produce a smoother floor

- Reduced penetration

- Less bucket spillage between tips

Penetration Plus

- Use in hard to penetrate, moderate to high abrasive materials

- Very good penetration

- Stays sharp

Penetration

- Use in hard to penetrate, low abrasive materials

- Very good penetration

- Stays sharp

Spike

- Use in very hard to penetrate, low abrasive materials

- Maximum penetration

- Cross section to maintain sharpness

Double Spike

- Use in hard to penetrate, fracturable materials

- Excellent penetration

- Use at corner positions with spike centers

WARNING

WARNING